Company Profile

Zhongshan Mingjie Stamping Die Co.,ltd. has been engaged in the research and development of High-speed Progressive Stamping Die for over twenty years. We continuously innovate and strive for excellence in single-row, double-row, three-row, four-row, and five-row technologies, and increase research and development investment to precision progressive mold stamping technology, expand our advantages, with technology and lean production as auxiliary, combined with automation, lean and customized production, to promote customized production of precision parts.

The high-speed progressive stamping dies we manufacture cover a wide range of motor cores used for mass production, including water pump motors, Y-series motors, air conditioning compressor motors, refrigerator compressor motors, washing machine motors, air conditioning sealed motors, automotive motors, generators, stepper motors, and various types of induction motors, series-wound motors,shaded pole motors, brushless DC motors, AC and DC inverter motors, among others. The molds we produce can process stator and rotor core stampings with diameters ranging from Φ12 to Φ720mm,and can achieve self-locking, slant slots, and stepped hole punching for cores within the range of Φ12 to Φ260mm.

In recent years, We have successively exported to multiple countries, based on high-quality and high-end markets, and won the trust and praise of our customers with quality and low prices. Our customers are all attracted and flocking to us. The company always adheres to the ultimate goal of "creating value for customers", with the aim of "persisting and constantly surpassing", and wins the trust of customers with good and high-quality after-sales service!

20 years of experience

Large-volume supply

Customized services

After-sales service

Stamping Dies For Motor Core Lamination

We specialize in creating custom stamping dies that can meet the needs of our customers. Our precision engineering techniques allow us to produce highly accurate stamping molds perfect for motor lamination projects.

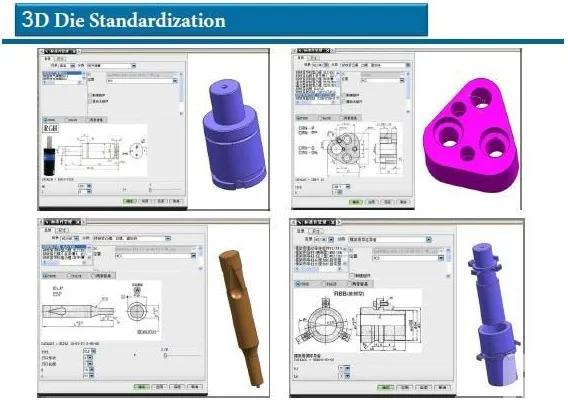

We are proud to announce that we have our mold research and development team, from design to production to follow-up maintenance. Our R&D team consists of experienced design engineers, tool makers, and technicians with many years of experience in the mold industry. With their expertise, we can help bring your ideas from concept into reality.

Our Stamping Dies Manufacturing Capabilities

We specialize in designing and manufacturing custom-made stamping dies for motor core lamination. Our experienced team can provide consultation and advice on your tooling needs. We use advanced CAD/CAM software to ensure accuracy in designing and manufacturing our motor core stamping molds. Therefore, we can stamp motor laminations for many industries.

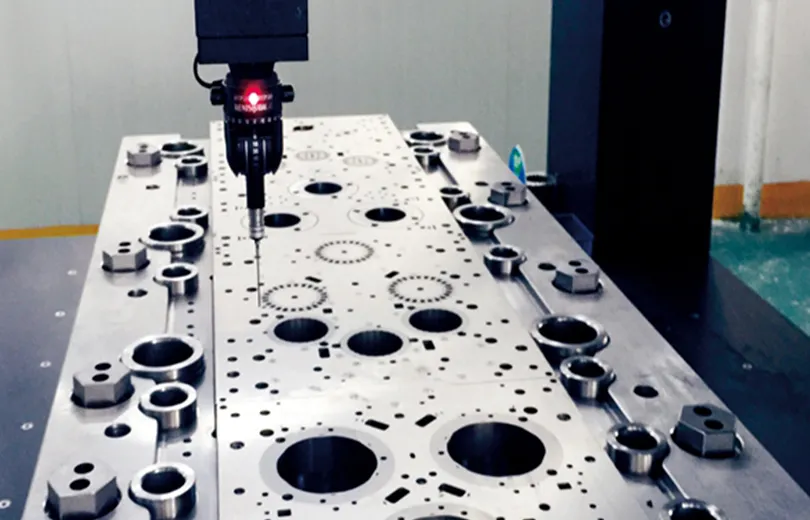

Our dies manufacturing capabilities include CNC machining, EDM, wire EDM, and surface grinding. Our stamping molds are designed with precision, meticulous engineering, and high-quality materials to ensure long-lasting quality.

Wire EDM Cutting

Wire EDM cutting is a process that uses an electrical current to cut small, intricate parts from metal. It can create stamping dies for motor core lamination stack, offering high precision and accuracy and producing parts with tight tolerances and complex geometries.

We use a slow wire EDM cutting machine for plate parts, punch and die. The dimensional tolerance is 0.002mm to ensure the die performance does not change when the parts are exchanged.

CNC Milling and Grinding

We specialize in the production of high-precision stamping dies for motor core lamination. Our CNC milling capabilities allow us to produce intricate and detailed parts with tight tolerances.

We process the lock pin, the punch and die groove, and the punch’s central hole by PG grinding. The surface of each part will be smoother and wear-resistant. Dimensional tolerances will be less than 0.002 mm, improving blade accuracy and stability. As a result, the mold life will be longer.

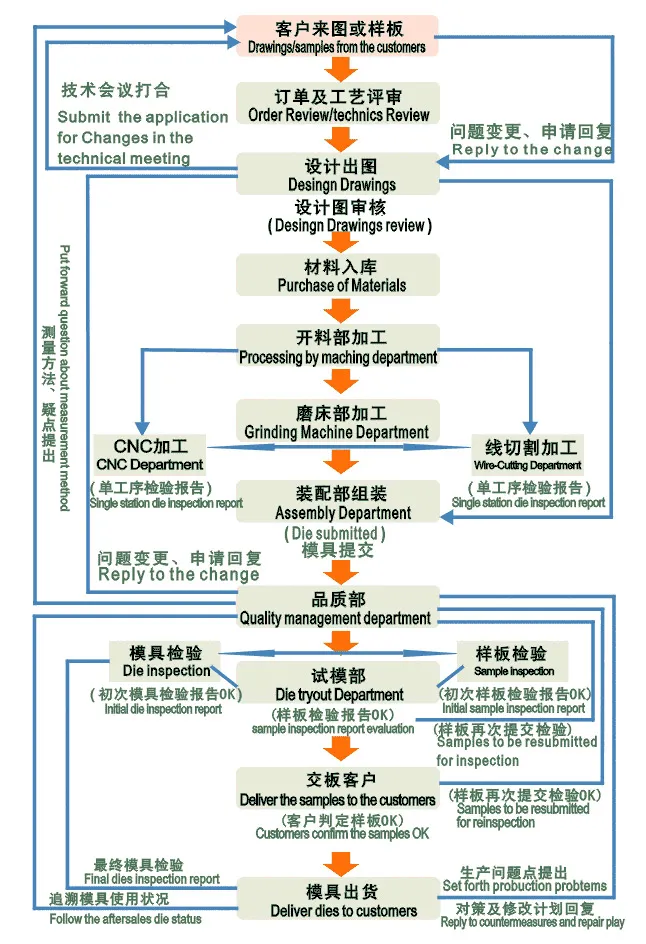

Quality Control

Our Partners

Talk With Our Experts